CNCGLASS

Glass Hardware Glass Connectors and Stabilizers

CNCGLASS

Glass Door Handle Knobs

Glass Door Handle Knobs

CNCGLASS

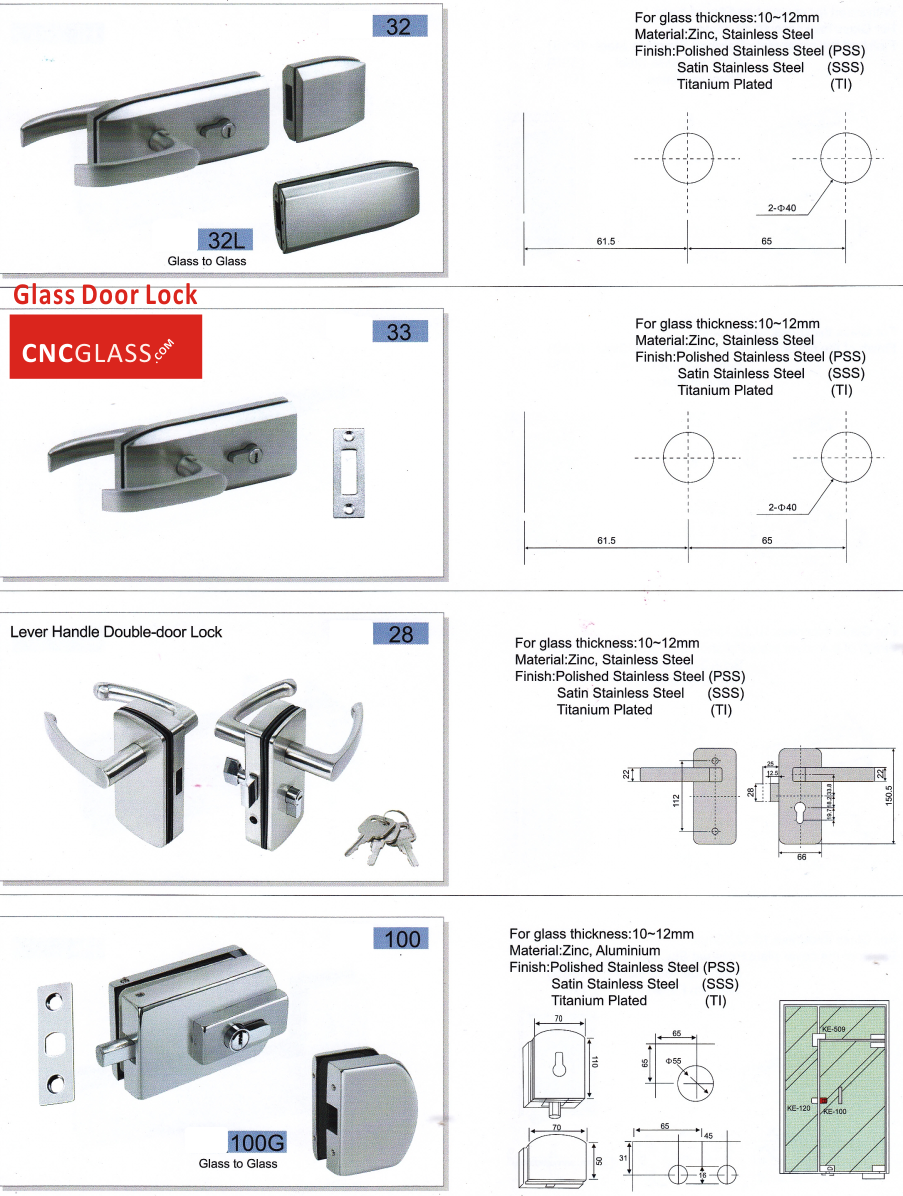

Glass Door Lock

Silicone Vacuum Bag for EVA Glass Laminating Furnace

Silicone Vacuum Bag for EVA Glass Laminating Furnace

CNCGLASS

Silicone Vacuum Bag for EVA Glass Laminating Furnace Oven

Silicone Vacuum Bag for EVA Glass Laminating Furnace Oven

Each set of integrity silicon blanket consists of one top and one bottom silicone sheets. The four

top and bottom sheet edges are sophisticatedly embedded to each other, to make sealed room for vacuuming. Interlocking of edges and corners are easy. Edges and corners are specially modified , such as locking strength grows larger when vacuum pressure becomes higher. Although it is tightly sealed, edges unlocking and opening are amusingly easy when vacuuming stops.

Silicone Blanket Data sheet

Hardness

55±5(Shore A)

Tensile Strength

≥11.2 Mpa

Tearing Strength ≥38N/mm

Long Run Temperature 250℃

EVA Resistance Strong

Normal Using Life >3000 cycles

Appearance One side smooth and one side cloth

Remarks Maximum width: 4000mm without joint, the world’s first

Product features: heat-resistant, high elasticity, special surface property (no adhesion) and

physiological inertia, oil resistant, solvent resistant, anti-aging, anti-corrosive, and non-polluting.,EVA resistance.

Tensile Strength

Top silicone blanket is more flexible. When vacuum is turn on, air in between top and bottom silicon sheets starts to evacuate. Top silicone blanket begins to wrap downwards along glass edges until it gets in physically zero-gap contact with bottom silicone sheet. No air or gap is allowed in between the two silicone blanket. This specially formulated silicon blanket is highly elastic. It provides enough flexibility, allowing the blanket to stretch until it fully wraps along glass edges. This remarkable property is especially important when glass is thick and/or curve.

Heat Resistance

Silicone sheet resists high temperature(more than 250C). Uniform Heating is applied on silicon blanket and glass all the time until interlayers, for example, EVA film is melted thoroughly. High temperature resistance is one of the important criteria of silicone vacuum blanket.

Thermal Stability

After heating is completed, forced cooling is started. Silicon is thermally stable for numerous rise and fall of temperature.

Silicon blanket is tough. It allows glass loadings and unloading for numerously times. It resists abrasion, wear and tear up to a certain high degree. But to protect the silicone vacuum bag, it’s better you edging the glass before laminating.

While the blanket is strong, the blanket is also soft enough for easy handling when top blanket is

opened and closed during glass loading and unloading.

Thanks to special formula, silicon blanket is deterioration proof. Its properties

retain unchanged.

When the blanket is always kept clean, handled properly and glass edge is polished, the

blanket is long lasting.

Silicon Tube of highly flexible silicon tube is provided. It connects from silicon blanket to

vacuum system. Air in between top and bottom sheets is evacuated through this silicon tube to vacuum system. 4 meter of silicone tube will be provided with each vacuum hose.

If you need more EVA laminating accessories, please contact us: EVA THERMAL CUTTER,

SILICONE VACUUM BAG,

LIGHT MEASURING EQUIPMENT,

GREEN RIBBON TAPE

All rights reserved by

UCOLIN GLAZING SUPPORT

GUANGDONG,CHINA

WWW.UCOLIN.COM

Main Products: Silicone vacuum bag for EVA laminating furnace, Silicone Sheet, Glass Edging Wheels, Polishing Powders.

CNCGLASS

Howto Glass Laminating EVA Film Loading Container

EVA Glass Laminating Furnace(EVA Film, Silicone Vaccum Bag,Laminated Glass)

5 Layers; Door open in 2 Sides

5 Layers; Door open in 1 End

2 Layers; Door open in 2 Sides

2 Layers; Door open in 1 End

1 Layer; Door open in 2 Sides

CNCGLASS

EVA Glass Laminating Furnace(EVA Film, Silicone Vaccum Bag,Laminated Glass).pdf

Cerium Oxide CeO2 Jade Polishing Powder 668-4

Cerium Oxide CeO2 Jade Polishing Powder 668-4

CNCGLASS

Cerium Oxide CeO2 Jade Polishing Powder 668-4.pdf

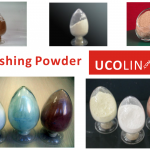

Cerium Oxide CeO2 Polishing Powder for Glass Polishing

Cerium Oxide CeO2 Polishing Powder for Glass Polishing

UC22

Applied in glass believing edging machine for polishing all kinds of glass edges.

CeO2/REO:74.56%

Cerium Oxide CeO2 Product Series

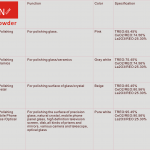

Name Function Color Specification

CeO2 Cerium Oxide Polishing Powder for Glass

UCO22 For polishing glass. Pink TREO:65.45%

CeO2/REO:74.56%

La2O3/REO:25.30%

CeO2 Cerium Oxide Polishing Powder for Glass/ Ceramics

UCO21 For polishing glass/ceramics Gray white TREO:75.45%

CeO2/REO:74.56%

La2O3/REO:25.30%

CeO2 Cerium Oxide Polishing Powder for Glass/ Crystal

UCO20 For polishing surface of glass/crystal Beige TREO:85.45% CeO2/REO:80.56%

La2O3/REO:25.30%

CeO2 Cerium Oxide Polishing Powder for Glass/ Mobile Phone Panel Glass/TV’s Glass /Optical glass, etc.

UCO19 For polishing the surface of precision glass, natural crystal, mobile phone panel glass, high definition television screen, disk,all kinds of prisms and mirrors, various camera and telescope,

optical glass Pure white TREO:95.45%

CeO2/REO:90.56%

La2O3/REO:25.30%

Implications:

Implication1- For glass industry additives, for plate glass polishing materials,has been extended to implied in precision glass, optical glass, optical lens, tube grinding,bleaching, clear, glass UV absorption lines and the role of electronic.

Implication2-For anti-reflective glasses lenses agent, and CE made of titanium yellow to pale yellow glass.

Implication3-Used in ceramic glazing and electronics industry, as agents penetrating the piezoelectric ceramic.

Implication4-For the manufacture of high-activity catalyst, gas mask incandescent lights, X-ray with the screen.

Operations

Operation1-Try to reduce the dust emission in the air, for example, by adopting wet process or closed operation system.

Operation2-Provide vacuum collecting equipment in places with dust generation possibility, and provide personnel with appropriate dust filtration respirator.

Operation3-Wash hands before eating or drinking anything and going off work, clothing with dust should be taken off and washed.

Storage:

Storage1-A proper container should be used and marked.

Storage2-A closed container or area should be used for storage and protected against collision.

All rights reserved by UCOLIN GLAZING SUPPORT:

Main Products: Silicone vacuum bag for EVA laminating furnace, Silicone Sheet, Glass Edging Wheels, Polishing Powders.

CNCGLASS